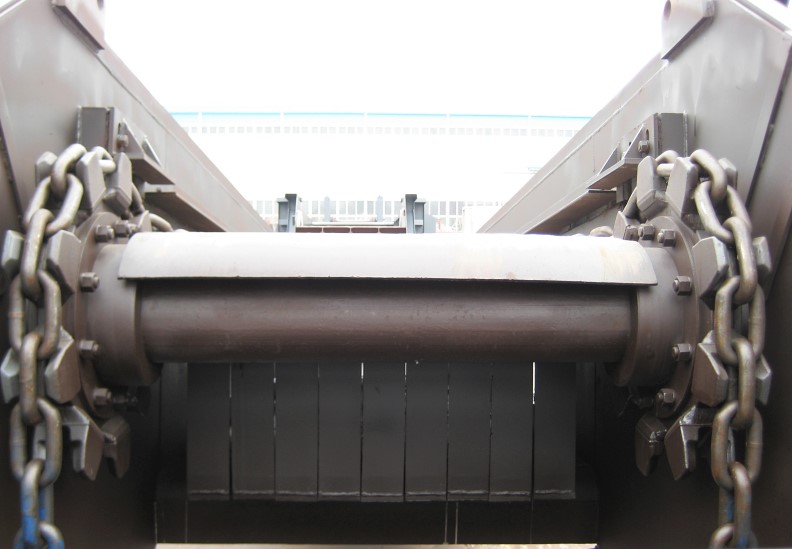

CICSA round steel link chains are well known for offering robust, long-lasting solutions and reliable results in a number of material handling applications, especially those featuring heavy loads and harsh operating conditions. When it comes to the transport of corrosive materials, operations at high temperatures and handling of extremely abrasive materials, round steel link chains have become a proven standard solution, offering unique advantages such as:

- High wear resistance and durability;

- Being self-cleaning;

- Easy monitoring and maintenance;

- Adaptability to almost any granularity.

The entire manufacturing process of CICSA round steel link chains is carried out at CICSA’s facilities, including welding, heat treatment and testing. Flash-welding is the most reliable and advanced welding system for this type of components.

Our heat treatment department, equipped with electric kilns operating under controlled atmosphere by means computerized analysers, is the pride of CICSA. Our test department includes advanced calibrating and testing equipment, a certified 30 metre long traction bench testing up to 120 tons (1200 kN) and a certified bench testing up to 250 tons (2500 kN).

The Research and Development department of our company, thanks to advanced CAD and software systems, allows smart and safe engineering of every component. Our laboratory regularly carries out metallographic surveys and mechanical traction, fatigue, resilience, hardness and micro-hardness tests.

For more than 70 years CICSA has been manufactured round steel link chains that have become a reference technology in the cement and concrete Industry, mining Industry, gypsum industry and power generation industry.