CICSA mechanical chains are synonymous of high quality, reliability, durability and safety. They cover a wide range of applications for any industry, especially those featuring heavy loads and harsh operating conditions.

CICSA mechanical chains are synonymous of high quality, reliability, durability and safety. They cover a wide range of applications for any industry, especially those featuring heavy loads and harsh operating conditions.

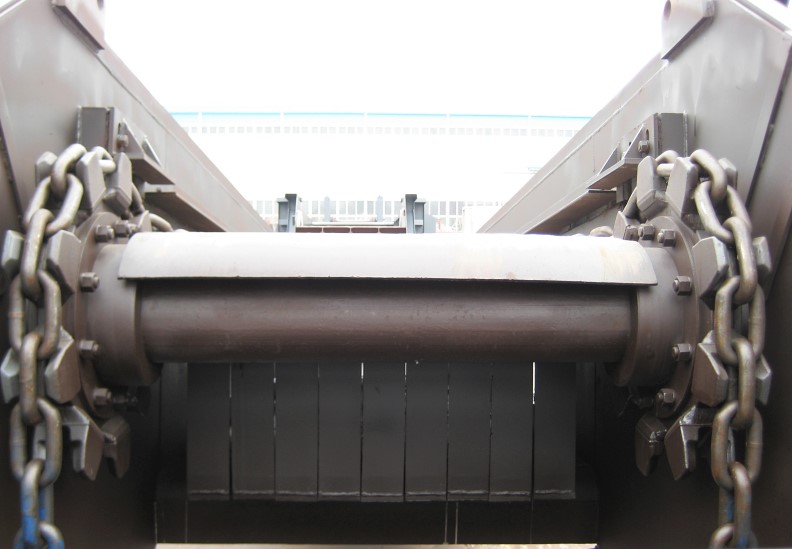

CICSA mechanical conveyor chains, bushing chains for elevators, central chains and forged chains are available in various versions, with different types of attachments, to meet any requirement and find the most suitable solution for conveying any material.

Chains are manufactured with different top-quality materials, ranging among case-hardened alloy steel, carbonitrided case-hardened alloy steel, quenched alloy steel, induction-hardened steel and stainless steel.

We also produce fittings, such as sprockets, shafts, rollers and much more.

The Research and Development department of our company, thanks to advanced CAD and software systems, allows smart and safe engineering of every component. CICSA offers both standard and tailor-made solutions, but we also develop special conveyor and transport chains customised and optimised for customers’ requirements in all designs and dimensions. Our laboratory regularly carries out metallographic surveys and mechanical traction, fatigue, resilience, hardness and micro-hardness tests.

Our heat treatment department, equipped with electric kilns operating under controlled atmosphere by means computerized analysers, is the pride of CICSA. Our test department includes advanced calibrating and testing equipment, a certified 30 metre long traction bench testing up to 120 tons (1200 kN) and a certified bench testing up to 250 tons (2500 kN).

CICSA mechanical chains have become a reference technology in the cement Industry, ceramic Industry, chemical and fertiliser industry, bulk material handling industry and conveying industry in general.